The Ironwork Process at Anchor Iron Co.

At Anchor Iron Co. in Savage, Minnesota, we specialize in delivering custom ironwork that blends practicality, safety, beauty, and durability. Our process ensures each project is tailored to meet your exact needs while maintaining the highest standards of craftsmanship. Below, we break down every step of the ironwork process—from consultation to final installation.

Planning & Consultation

Every successful project begins with a clear plan. Our process starts with a consultation, where we meet with you in person or via phone to discuss your ideas and requirements. We take the time to fully understand your needs, provide expert advice, and help refine your vision. Our goal is to align our craftsmanship with your expectations, ensuring a perfect result.

Field Measurements

Accurate on-site measurements are crucial to ensuring that your custom ironwork fits perfectly. After your consultation, we visit your location to take precise measurements of the space where the ironwork will be installed. This step ensures that the final product fits seamlessly into your home or business and meets all your design specifications.

Fabrication—Crafting Your Ironwork

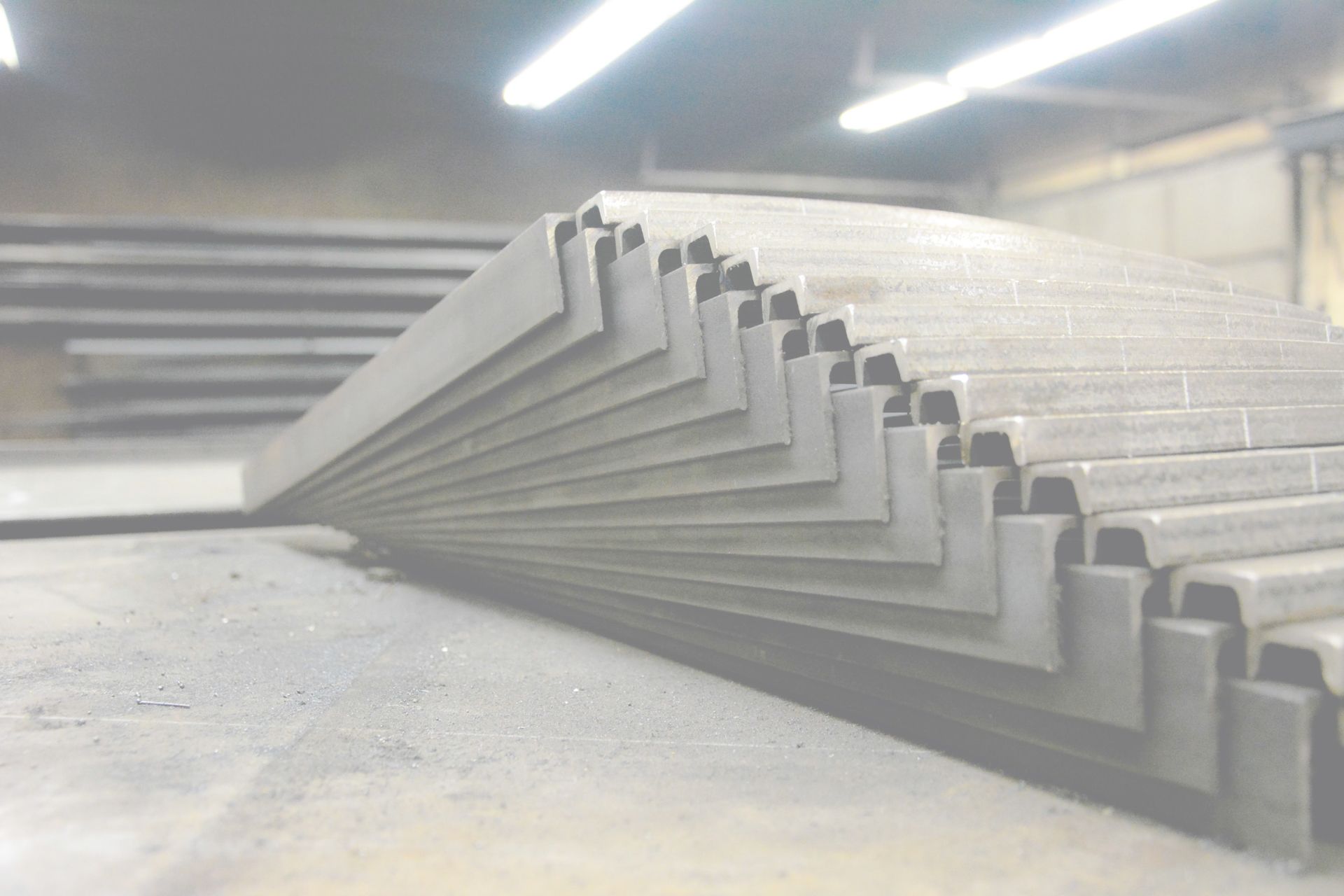

Once we have the measurements, the fabrication process begins. We select high-quality steel from our stock—typically in twenty-foot lengths—to begin creating your custom ironwork. This ensures that your project starts with the best materials for strength and durability.

Cutting: The steel is cut to size based on the specific requirements of your project. Each section is carefully measured to ensure it aligns with your design.

Assembly: The cut parts are laid out on a welding table, where we meticulously check angles, alignment, and spacing. Precision is key at this stage to guarantee a flawless outcome.

Welding: With everything in place, the parts are welded together. This process permanently joins the components, creating a strong and durable structure.

Grinding: After welding, we smooth the welds through a grinding process. This ensures the joints are seamless and the ironwork has a polished, professional appearance.

Finishing—Protecting & Beautifying

The finishing process gives your ironwork both beauty and durability. We apply a three-part coating to protect the steel and enhance the appearance of the final product:

Dipping: The iron is dipped to ensure complete coverage and protection.

Primer coat: A primer is sprayed on to create a solid base layer.

Finish coat: Finally, we apply the finish color of your choice, giving your ironwork a beautiful and long-lasting finish.

This multi-layered process not only improves the aesthetic appeal but also provides a protective barrier that ensures your ironwork remains easy to maintain and withstands the test of time.

Installation—Bringing Your Vision to Life

Once your ironwork is fabricated and finished, it’s time for installation. Our expert team of installers brings the completed pieces to your location and installs them according to the plan. We take great care in securing and positioning the ironwork, ensuring that it fits perfectly and functions as intended. Whether it's a staircase railing, fireplace surround, or custom door, we make sure everything is placed accurately and securely.

Communication—Staying Connected Every Step of the Way

From the initial consultation to the final installation, communication is key. We keep you informed at every stage of the process, from scheduling meetings to providing progress updates. You’ll always know exactly where your project stands, and if any questions arise, we are just a phone call or email away. We pride ourselves on being responsive and available throughout the entire process.

Warranty—Our Promise to You

At Anchor Iron Co., we stand behind our work. After your project is complete, we provide a written lifetime warranty on the ironwork, ensuring that you have peace of mind for years to come. Additionally, we offer industry-standard warranties on the materials used in your project, so you can rest assured knowing your investment is protected.

Why Choose Anchor Iron Co.?

Choosing the right company for your custom ironwork is essential. At Anchor Iron Co., we combine expert craftsmanship with unparalleled customer service. With years of experience in the industry, we guarantee that your project will be completed to the highest standards. From planning and consultation to installation and warranty, we ensure that your ironwork is crafted with precision, care, and dedication.

Are you ready to get started with your custom ironwork project? Contact Anchor Iron Co. at 952-445-3030 to schedule your consultation today!